- Best Sellers

- Outdoor Structures

- Safes

-

Hydraulic Cylinders

- Agricultural Clevis Cylinders

- Cross Tube Hydraulic Cylinders

- Clevis End Hydraulic Cylinders

- Dump Trailer Cylinders

- Pin Eye Hydraulic Cylinders

- Tang Hydraulic Cylinders

- Loader Hydraulic Cylinders

- Log Splitter Hydraulic Cylinders

- Telescopic Hydraulic Cylinders

- Swivel Eye Hydraulic Cylinders

- Snow Plow Hydraulic Cylinders

- Tie-Rod Hydraulic Cylinders

- Rephasing Hydraulic Cylinders

- Hydraulic Power Units/Pumps

- Hydraulic Valves

- Saddles

-

Milking Equipment

-

Portable Milking Equipment

- Replacement Parts for Quarter Milkers

- Portable Milking Machines for Cows, Goats, and Sheep - Base Units - Include Vacuum Pump + Motor

- Complete Portable Milking Machine Packages

- Bucket Milker Assemblies

- Milking Clusters - Claw Assemblies

- Pulsation Equipment

- Claws & Shells

- Milking Buckets

- Just Lids

- Nupulse Parts for Milkers

- Quarter Milkers

- Surcingles

- Goat & Sheep Milking

- Consumables & Supplies

- Pipeline Milking Equipment

- Home Processing

-

Portable Milking Equipment

- Hopper Bins

- CIP Washing & Sanitizing

- Feeders & Waterers

-

Animal Care

- Artificial Insemination

- Scratchers & Oilers

- Animal Identification

- Calf Jackets

- Horse Turnout Blankets

- Neck Straps & Halters

- Cattle Lifts - Cow Lifters

- Dairy Udder Health

- Stomach Pumps & Accessories

- Dehorning Equipment

- Fly & Pest Control

- Measuring / Weighing

- Clipper Supplies

- Animal Handling & Control

- Milkhouse Barn & Parlor Equip

-

Rebuilt Dairy Pumps

-

Dairy Vacuum Pumps

- Bou-Matic: FR3-A, FR4, FR4-A, DB-2000, VP-155

- Delaval: 76, 78, 84, 777

- Duraflow: 4504, 4506

- Masport: M-3, M-4, M-5, M-7.5, M-15

- Surge: 30Plus, 40Plus, 75Plus, 100Plus, 2300, 2800

- Sutorbilt: 2-M, 3-H, 3-M, 4-H, 4-M, 5-H, 5-M, 6-H, 6-M, 7-H, 7-M

- Tuthill: 3303, 4002, 4005, 5003, 5006, 6008

- Westfalia: RPS2800

- Takeoffs

-

Dairy Vacuum Pumps

- Cattle Guards

-

Parts

- Vacuum Regulator Parts

-

Water Bowl Replacement Parts

- Nipple Drinkers CP10, CP11, CP13, CP14, CP15, CP16, CP17, CP21

- Strangko Cast Iron Water (NS61) Bowl Parts

- Forstal Paddle Water Bowl (644-3261) Replacement Parts

- Deluxe Cast Iron Waterer (AU82C) Replacement Parts

- Deluxe Cast Iron Water Bowl - High Flow (AU82C-SF) Replacement Parts

- Deluxe Plastic Water Bowl (AU82P) Replacement Parts

- Deluxe Plastic Water Bowl - High Flow (AU82P-SF) Replacement Parts

- Push-Button Waterer w/ Galvanized Bowl (M81) Replacement Parts

- Poly Float Bowl (MA04) Replacement Parts

- Push-Button Waterer w/ Plastic Bowl (M81) Replacement Parts

- Strangko Nylon Water (NS77) Bowl Parts

- Plastic Cattle Water Bowl (PCBLS) Replacement Parts

- Super Flow Plastic Water Bowl (RP-02) Replacement Parts

- Large Round S.S. Super Flow Water Bowl (RSS-02) Replacement Parts

- Galvanized Float Bowl (S76) Replacement Parts

- Stainless Steel Water Bowl--Deep Dish (S76SS) Replacement Parts

- Deluxe Red & Black Float Bowl (S91) Replacement Parts

- Push-Button Hog Bowl (75) Replacement Parts

- Bucket Milker Parts

- Hose Management Accessories

- Milking Claw Parts

- Pasteurizer Parts

- Porta Scale Parts

- Vacuum Pump Vanes Replacements

- Water Bowl Replacement Parts

- Butter Churn Parts

- Parts & Power Supplies

- NEW!

- Home Brewing

-

Outdoor Furniture

- Dining Sets

- Porch Swings

- Outdoor Rocking Chairs

- Wooden Adirondack Chairs

- Seating Sets

- Chaise Lounges

- Bistro Sets

- Outdoor Dining Tables

- Outdoor Dining Chairs

- Outdoor Bar Furniture

- Coffee Tables & Side Tables

- Deep Seating

- Outdoor Benches

- Patio Umbrellas

- Umbrella Bases

- Outdoor Plant Stands

- Wagon Wheels

- Chicken Coops

- Power Equipment

- Farm Gates & Fencing

- Apply for Financing

Grain Bins for Sale - Storage Bin Options and Pricing

Grain storage is critical to the success of selling and marketing quality products. Over the last couple of years, low commodity prices traditionally caused some farmers to store more grain. When you are storing grain for lengthier time periods, knowing correct storage options is crucial to keeping grain in great shape.

Grain silos and bins are among the most popular kinds of grain storage options on the market these days. If you are considering a silo or bin for your farm, you first should know their differences. They’re made for various purposes, and the details below will assist you in deciding which one you need.

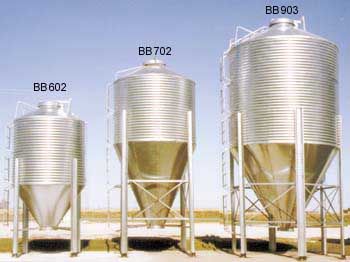

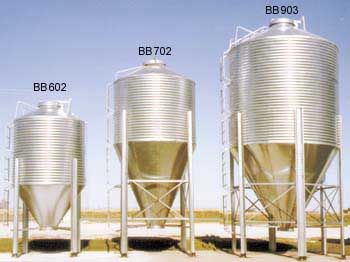

Example of some of the sizes we carry.

Example of some of the sizes we carry.

Differences Between Silos and Grain Bins

Grain Storage

Silos and bins store various kinds of grain. Bins store dry grains such as soybeans, seeds, barley, wheat, oats, and shelled corn. Normally, those are sold to make fuel or for human consumption. On the other hand, silos store silage that are fermented grasses which are stored to feed cattle and various livestock in the wintertime.

Appearances

Also, silos and bins appear a little different. Both are cylindrical, yet grain bins usually differ in shape. They may be slender and tall or wide and squat. Normally, they have peaked roofs and are designed of metal. Grain silos usually are slimmer and taller and have a domed roof.

Functions

Each option of grain storage has various functions. The purpose of the grain bin includes keeping the grain free of pests, undamaged, and dry. It has to enable enough aeration, as well as maintain humidity and temperature levels to keep the contents from spoiling. The purpose of silos includes promoting fermentation—that is, the breakdown of grasses by bacteria and additional microorganisms—in order to preserve its contents.

A lot of bins are short, wide buildings consisting of smooth and corrugated metal. A grain bin possesses a more uniform shape than a silo will, and has a peaked roof and cylindrical body. Oftentimes, you will see doors and ladders on its sides. A grain bin has more ventilating components — such as temperature systems and roof vents — than a silo because it’ll require a sufficient amount of airflow. Although small farms utilize grain bins, they also are common to bigger grain storage centers.

Grain Bin Features

Grain bins have a number of features that work with each other to assist them in accomplishing their responsibility of storing and protecting agricultural goods. Below is a list of some standard elements you will find inside grain handling systems.

Cushion box: It safeguards the grain from becoming damaged during a free fall by softening the landing. Occasionally kernels may break or crack after undergoing spouting, lowering the market value of the product. The quality of grain is critical to accomplishing a good ROI, which is the reason why an efficient cushion box is needed for a grain storage center.

Flow valves: They control how slowly or quickly grain travels through grain handling systems. Also, they allow you to manage the amount of grain moving through, facilitating or stemming grain flow as it’s needed. Our full flow valves provide you unlimited movement, which prevents costly and time-consuming mistakes such as grain leakage and cross-contamination.

Slide gates: Once you require a handling option for bulk materials, a slide gate should be your go-to option. A slide gate controls grain flow at a discharge point like a hopper and an emergency shut-off site. Installing slide gates will prevent grain leakage and seize-ups — it’s possible to guard your profit and your grain.

Grain Bin Applications

Compared with a silo, what will a grain bin store? A grain bin can store grain products such as oats, soybeans, barley, etc. The difference in silos and grain bins is that the containers have to keep those products dry until they are shipped — in addition to being pest-free and uncontaminated. Moisture retention may cause these goods to spoil, yet applying an overabundance of heat may facilitate shrinkage, reducing your profit. A temperature and ventilation system keeps the environment at the perfect equilibrium.

Farmers utilize those grains for fuel, animal food products, and human’s food products. If it is a matter of a silo versus a grain bin, a grain bin is the option to select once you have to protect your products against dampness. Also, corrugated or smooth walls might play a part in storage as far as grain quality, grain quantity, and pest control is concerned.

Benefits of using small to medium sized grain bins used on farms

In today’s agriculture industry, storing grain after harvest is a typical operator practice. The main purposes for doing this include:

Grain might be used slowly throughout the year for feeding livestock.

The capability of conditioning grain for optimal value.

Less than stellar weather conditions within the harvest months.

Storing grain will assist you in capturing the “carry” within the market.

Flexibility in where and when a crop is sold.

Traditionally, building a storage bin upon a farmstead has been favored due to the control and maximum flexibility the operator has over the cost the crop gets sold at. Of course, this is a gamble and costs might not rise after the harvest months.

One other benefit of on-farm bins is the capability of conditioning the grain before you sell it. If “damp” grain is brought over to an Ag cooperative you’ll get a reduction in commodity value. It’s possible to lose from .10 to .20 cents a bushel.

For instance, if a farmer brought in 50,000 wet grain bushels from a field, and is docked .20¢/bushel you’re looking at a loss of about $10,000 upon 50,000 bushels. If farmers stored grain within on-farm grain bins then conditioned the grains, they might gain $9000 of the exact same 50,000 bushels—considering there’s always a bit of dockage applied. Take that example and apply the figures to it. The funds you obtain from 6 years of that practice will pay for the system. Match it with the capability of watching the market and selling as costs are greater than during the harvest period and you’ll have paid for the bin in less than three years.

In turn, it also provides farmers the capability of harvesting earlier and drying their commodities. Farmers are not waiting until the fields dry sufficiently then risk the weather changing yet again. During this time you might be risking molding and sprouting on the grain, which once again, decreases the profit.

Recently, that occurred in the state of Idaho. Crops were getting close to harvest and the earth continually rained and sprouted the barley. A portion of the barley was contracted with Anheuser Busch; but farmers were told that they had to store the crops for at least three months before reps at Anheuser Busch would have to test out the barley to check if it met their standard. If you do not have a system up and running, not only are you going to need to pay conditioning fees and rent space, you might not have the ability to sell the crop at the end of the day.

Having on-farm storage systems is beneficial, yet like the majority of things they have their disadvantages. One is trucking the crop from a field directly to the elevator can be a time saver. You will not spend any time filling the trucks up another time then hauling to the elevator, which carries extra manpower and fuel costs.

Depending upon the Ag Cooperatives in your area, storage rates may be reasonable, in addition to saving you the expense of on-farm systems. There definitely are years that prices are right, crops are drying perfectly, elevators have space, making it more affordable to directly take in the crop.

With farmers getting more and more bushels/acre, storage is the main subject that has to be considered whether you select a coop or an on-farm storage system.

So let’s recap:

Working the land in order to earn a living is a game of chance. Oftentimes, ranchers and farmers are at the mercy of the elements to offer the required components for profitable success.

There is no way to control the elements, but there are specific measures ranchers and farmers may take to boost the probability that things are going to work out in their favor. Installing grain bins as an on-site storage solution is a key one.

Grain Storage Bin Benefits

In several ways, grain bins have been a staple of ranch and farm life for a long time. As farms work to thrive around the nation and commercial farming increasingly becomes the standard, the storage options are more critical now than ever before.

An on-site grain bin provides an easy alternative to working with local merchandisers and grain elevators whose prices consistently fluctuate according to their demand. Also, they offer the important protection from the weather elements that ranchers and farmers depend on to keep their grain in high-quality condition all year long.

Drying grain may be a time-consuming and costly process. The ones who purchase on-site grain bins are going to cut down on drying time, as well as open up solutions in terms of selling in accordance with fluctuations in the market.

Versatile Bin Options

In the past, grain bins were metal, standardized structures with very little variation in size. These days, the reality is different.

Now, ranchers and farmers appreciate a versatile lineup of options, ranging from metal, durable structures in various sizes to bulk and lightweight poly bins. Within the modern realm of ranching and farming, it is typical for a blend of grain bin structures and styles to work best for operation small and large.

Ranchers and farmers will discover that both poly and metal bins offer a great level of successful storage whether they are wanting to place pellets, grains, or seeds. Having those solutions available permits for fitting the on-site storage needs to your unique land requirements.

Metal Grain Bins

Oftentimes, metal grain bins are still the preferred solution among consumers in terms of grain storage for the long term. The durability of metal surfaces (usually galvanized steel) offer the assurance that those structures are going to pay for themselves in the long-term. Also, the capability of adding special accessories to metal bins like auger kits, ladders, and stiffeners make it convenient to customize the bin according to the requirements of a ranch or farm.

Poly Grain Bins

A poly bin tends to be an excellent choice for feed storage because of its semi-translucent facade that offers ranchers and farmers a view of refill levels. A smooth poly surface keeps grain from clogging and is much lighter in weight than its metal counterparts.

More Considerations and Pricing

The market and the weather might fluctuate yet having grain storage bins directly on-site means ranchers and farmers never need to be concerned with changing their prices in order to meet communal storage demands. It also is vital that you consider the truth that accessibility to on-site grain bins will mean more freedom in terms of determining a profitable schedule for harvest.

Prices can range from less than $2000 for the smallest hopper bins ( approximately 70 bushel capacity) up to about $5000 for a larger bin (approximately 600 bushel capacity). Also, when buying a hopper bin online, it is important to keep in mind that these products will need to be delivered by a freight truck and assembly will be required.

Grain Bins for Modern-Day Agriculture

Farm and Ranch Depot may assist you in designing quality grain bins that store your products, as well as gain the most from your agricultural business. Efficient grain handling systems are determining factors in the success of grain storage facilities. Where there are bins, there are dependable elements making everything possible.

Get in touch with our team right away for more details on starting your grain bin research. For assistance in planning your storage needs, take a look at all of our grain bins on Farm and Ranch Depot here and inform us on how we might help with anything at all. We can ship any grain bin (large or small) to anywhere inside the continental United States.

If you’d like a price quote or have any questions, please get in touch with us at 928-951-8332.